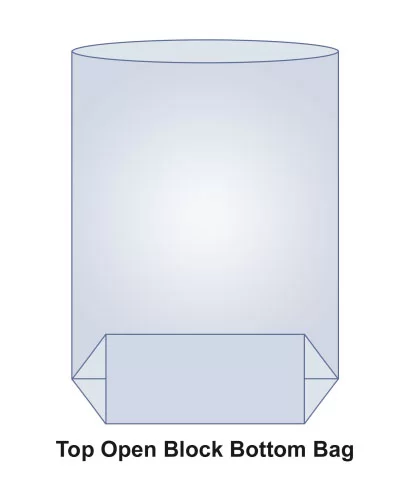

Block Bottom Bag – Top Open

Top Open Block Bottom Bags are designed with an open top, ready to be filled with your contents. Once you've filled them to the brim, they can be neatly sewn shut or securely sealed with a strip of tape. It boasts exceptional strength, along with resistance to water, adverse weather conditions, rough handling, and tearing. Moreover, it exhibits variable permeability and is both recyclable and reusable, making it highly appropriate for use in the pallet storage of brick-shaped packaging bags.

-

Manufacturing process

The unique charm of block bottom bags lies in their assembly process, where they are meticulously crafted using hot air welding, a method that eschews adhesives. Unlike other industrial bags, the base of these pouches is elegantly gusseted at the sides and securely sealed. Additionally, vertical sides are thoughtfully creased to ensure the bag stands firmly and proudly on store shelves. Typically, these top-open block bottom bags grace non-automated packaging stations, especially for products like chemicals, fertilizers, and plastics, which come in granular forms.

The Ad*Star® Bag, patented globally by Starlinger, is crafted with care exclusively on Starlinger machines. We are proud to say that we have been the leading Ad*Star Bag manufacturer since 2009 right here in China

-

Product features

Embrace Multi-purpose Convenience with Just One Bag

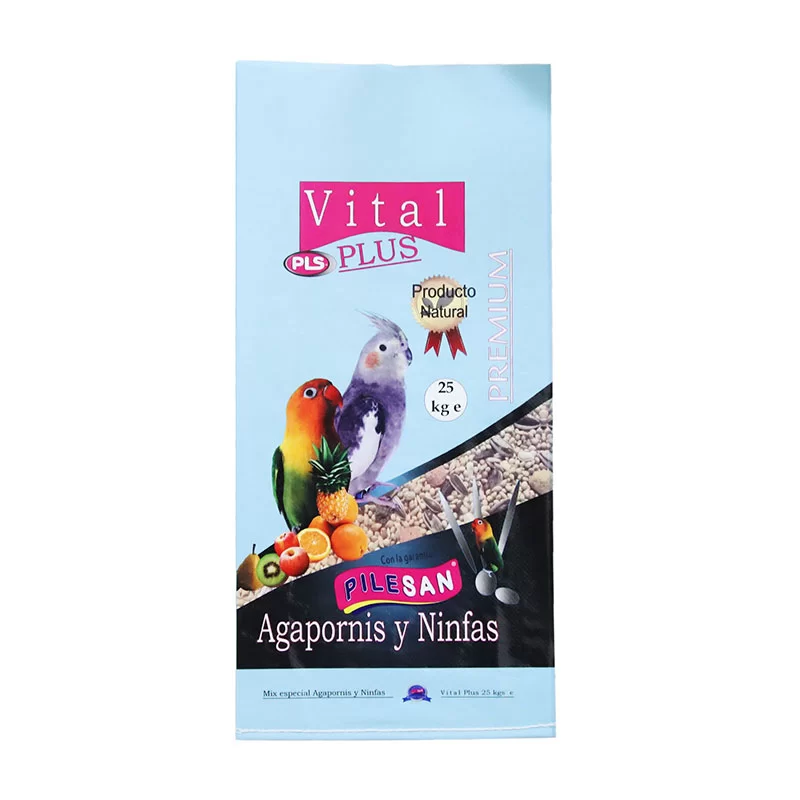

Block bottom bags have flat bottom for hassle -free filling and stacking for a wide range of free-flowing bulk materials, such as cement, building materials, fertilizers, chemical products, and granular substances, are also suitable for flour, sugar, and animal feed.

Experience the Ultimate in Customization and Ingenious Packaging

BOPP Laminated block bottom bag is BOPP Laminated fabric that makes into block bottom bag. Block bottom bag with BOPP laminated fabric will be more durable and fancy since BOPP film on the fabric is an extra protection. Besides, it supports customer design on bottom, top and sides because of the structure of bag, increasing recognition for bags stacked on shelves or pallets.

Elevates the Value of Your Brand with a Gentle Touch

Not only is it incredibly robust and highly resistant to harsh weather conditions, but it also allows for vibrant full-color printing and features transparent windows to beautifully display the products inside. When it comes to burst resistance, it outperforms all comparable products on the market, offering versatility and economy in one package.

Explore Efficient Industrial Packaging Methods to Make Your Work Easier

Adding to its appeal, the variable permeability ensures versatility, while its recyclable and reusable nature is ideal for efficient pallet storage of brick-shaped packaging bags.

-

Applications

These bags are neatly folded at the edges and heat sealed at the top and the bottom. The top position of the bag can be equipped with a valve structure for hassle-free automatic filling, making these bags ideally suitable for streamlined packaging needs in industries like cement, animal feed, chemicals, and fertilizers.

-

Specification

Material

100% Virgin Polypropylene ( PP )

Fabric color

White / Transparent/ Color

Printing

Flexo or Rotogravure

Width

35cm to 60cm

Length

50cm to 90cm

Mesh

8*8 /9*9 /10*10/12*12

Denier

From 600D to 1500D

Weight

50gsm-120gsm

Top

Top open

Bottom

square bottom

Characteristics

moisture-proof, tightness, highly tensile,tear resistant

Optional choice

inner coated, side gusseted,back seam

Perforation

microSTAR perforation

Printing color

1-8 colors

Certificate

BRC ISO9100

Appearance

glossy/matt lamination, UV stabilization , anti skid, anti-slip

Hit enter to search or ESC to close